Exploring the Benefits of Burnout Fabric Processing in China’s Mosha Velvet Factories

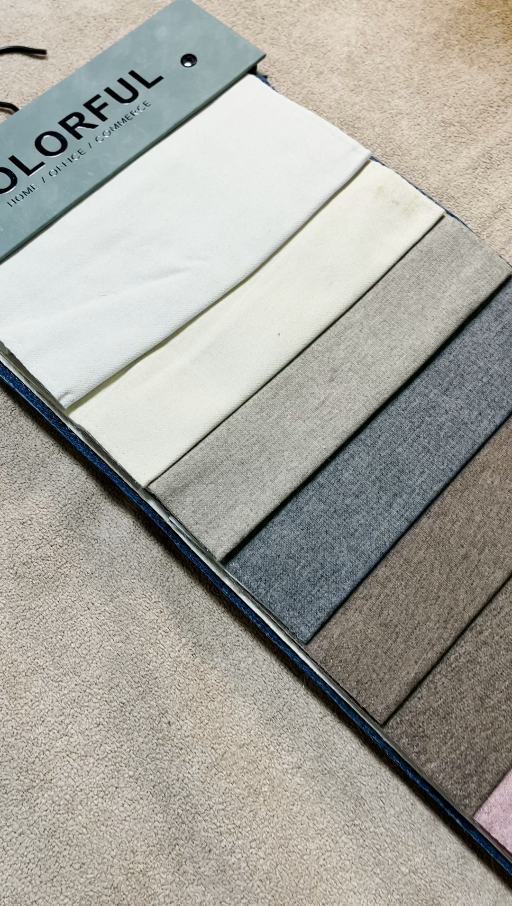

China’s Mosha velvet factories have long been renowned for their high-quality fabrics and intricate designs. Recently, however, the factories have begun to explore the benefits of burnout fabric processing, a technique that involves the use of chemicals to create unique patterns and textures on the fabric. This process has the potential to revolutionize the way Mosha velvet is produced, offering a range of advantages to both manufacturers and consumers.

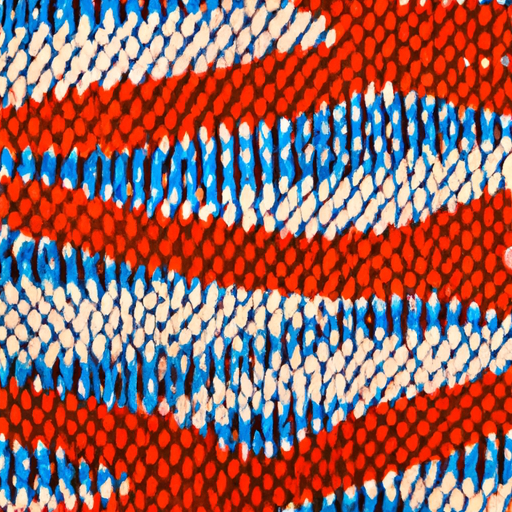

Burnout fabric processing is a relatively simple process that involves the use of chemicals to create unique patterns and textures on the fabric. The chemicals are applied to the fabric in a specific pattern, and then the fabric is exposed to heat. This causes the chemicals to react with the fabric, resulting in a unique pattern or texture. This process is often used to create intricate designs and patterns on fabrics, such as floral or geometric patterns.

The use of burnout fabric processing in Mosha velvet factories offers a number of advantages. Firstly, it allows manufacturers to create unique and intricate designs on the fabric, which can be used to create a range of products. This can help to differentiate the products from those of competitors, allowing manufacturers to stand out in the market. Additionally, the process is relatively inexpensive, making it an attractive option for manufacturers.

Furthermore, burnout fabric processing can also help to reduce the amount of waste produced during the manufacturing process. By using chemicals to create patterns and textures on the fabric, manufacturers can reduce the amount of fabric that is wasted during the production process. This can help to reduce the environmental impact of the manufacturing process, as well as helping to reduce costs.

Finally, burnout fabric processing can also help to improve the quality of the fabric. By using chemicals to create patterns and textures on the fabric, manufacturers can ensure that the fabric is of a higher quality than it would be without the process. This can help to ensure that the fabric is more durable and long-lasting, making it an attractive option for consumers.

In conclusion, burnout fabric processing offers a range of benefits to both manufacturers and consumers. By allowing manufacturers to create unique and intricate designs on the fabric, as well as reducing the amount of waste produced during the manufacturing process, this process can help to revolutionize the way Mosha velvet is produced. Additionally, the process can also help to improve the quality of the fabric, making it an attractive option for consumers.

Burnout fabric processing is a popular technique used in Mosha velvet factories to create unique and eye-catching designs. This technique involves the use of chemical agents to create a pattern on the fabric, which can be used to create a variety of different looks. In this article, we will explore the different types of burnout fabric processing techniques used in Mosha velvet factories.

The first type of burnout fabric processing technique used in Mosha velvet factories is called “dye-sublimation.” This technique involves the use of a special dye that is applied to the fabric and then heated to a high temperature. The heat causes the dye to vaporize, leaving behind a unique pattern on the fabric. This technique is often used to create intricate designs and patterns on the fabric.

The second type of burnout fabric processing technique used in Mosha velvet factories is called “screen printing.” This technique involves the use of a special screen that is placed over the fabric and then a special ink is applied to the screen. The ink is then transferred to the fabric, creating a unique pattern. This technique is often used to create bold and vibrant designs on the fabric.

The third type of burnout fabric processing technique used in Mosha velvet factories is called “embroidery.” This technique involves the use of a special needle and thread to create intricate designs on the fabric. This technique is often used to create delicate and intricate patterns on the fabric.

Finally, the fourth type of burnout fabric processing technique used in Mosha velvet factories is called “heat transfer.” This technique involves the use of a special heat press to transfer a design onto the fabric. This technique is often used to create bold and vibrant designs on the fabric.

In conclusion, there are four different types of burnout fabric processing techniques used in Mosha velvet factories. Each technique has its own unique advantages and disadvantages, and it is important to consider all of these factors when deciding which technique is best for your project.